What Are the Types of Automated Guided Vehicles? Expert Breakdown

Manufacturing facilities, together with warehousing and logistics operations, employ AGVs with LiDAR, machine vision, and path-planning to execute precise material transport operations that need repetition assurance.

Different types of automated guided vehicles exist with different load capacities and facility structures, thereby letting businesses grow operations without building tweaks. The automation of repetitive handling tasks through AGVs helps workers concentrate on advanced activities, which results in safer environments, lower costs, and accelerated order completion.

This article will discuss different AGV types, along with their features and applications.

What is an AGV?

AGVs serve facilities while retaining minimal human contact during pallet, tote, and raw material transportation. They link complex warehouse management systems in order to increase throughput while decreasing manual processing constraints.

Manufacturing plants contain various types of automated guided vehicles, which include towable tugger AGVs for heavy loads alongside unit-load AGVs for single pallet transport. The systems in some facilities may incorporate multi-level automated guided vehicles that operate vertically through rack structures. These transport systems depend on communication with superior software programs to accomplish task assignment duties and make live route adjustments during intensive periods.

How Does an AGV Work?

AGVs execute through accurate sensor combinations, which permit real-time path design and combine control loops that integrate odometry, inertial measurements, and environment mapping. The triangulated position of laser-guided units becomes precise to millimeter accuracy through their use of reflective targets combined with rotating laser scanners.

On the other hand, the magnetic systems integrate floor wires jointly with magnetic tape, which facilitates onboard sensors to track electromagnetic fields for automated path-following capabilities.

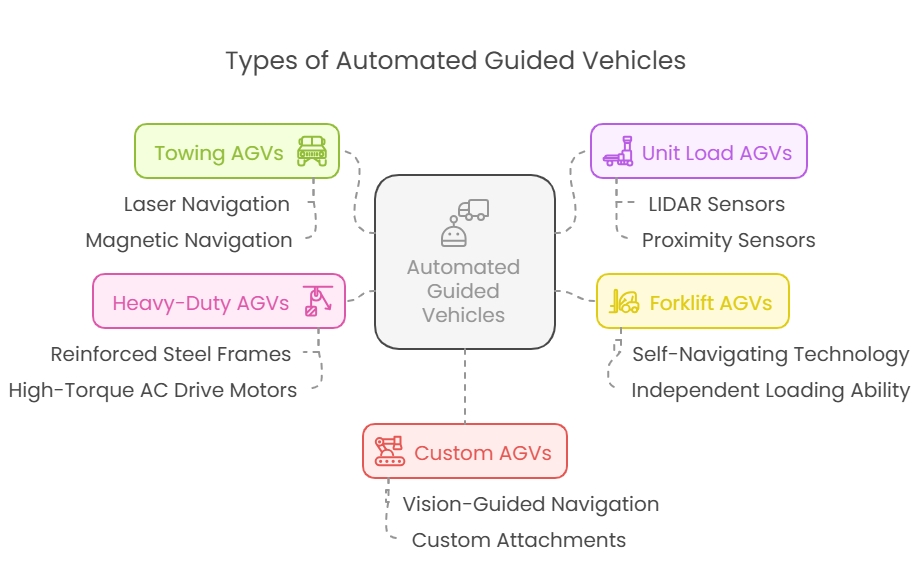

Different Types of Automated Guided Vehicles

AGVs come in diverse types, each designed to optimize specific material handling tasks with precision and efficiency.

Towing AGVs

Among the types of automated guided vehicles, multiple trailers are managed by towing AGVs, which operate as single units during each journey. Standard path-following operations for these vehicles utilize either laser or magnetic navigation systems. Many models have progressive traction control to cope with uneven flooring and tight corners.

Heavy-duty towing operations become more efficient with lithium-ion batteries that have high storage capacity. Thanks to modular hitch systems, automated vehicles can connect and release trailers quickly.

Unit Load AGVs

Unit Load AGVs are among the types of automated guided vehicles that transport either single pallets or totes through built-in conveyors or lift platforms. The equipment has adjustable lift tables that enable ergonomic pallet loading.

Sensor fusion combines LIDAR and proximity sensors while guaranteeing collision-free travel. Additionally, the newly developed versions of unit load AGVs include automated pallet identification systems through RFID tag technology.

Such autonomous warehouse vehicles are common because they require the exact positioning of loads.

Forklift AGVs

Among all the types of automated guided vehicles, Forklift AGVs stand out as the conventional form. The machines operate as automated versions of standard forklifts because they feature self-navigating technology along with independent loading ability.

Furthermore, stable lifting operations occur at different elevations through the use of high-precision encoders and inertial measurement units. Dynamic fork tilt control characteristics in certain models permit them to level pallets automatically. Cold-chain facilities heavily depend on these vehicles because their rugged construction elements work well in such conditions.

Heavy-Duty AGVs

Heavy-duty AGVs are one of the powerful types of automated guided vehicles that function to transport weights exceeding multiple tons. The vehicles use reinforced steel frames together with high-torque AC drive motors, which allow precise motion when dealing with extreme weight. The distribution of load pressure through multiple steering axles helps decrease surface stress on the floor.

This type of automated vehicle system may use subsurface detectors to actively track infrastructure conditions throughout its operating area. Heavy-duty automated guided vehicles operate in shipyards and steel mills to manage their frequent heavy load requirements.

Custom AGVs

Among the types of automated guided vehicles, the custom AGV tackles specialized tasks. The vehicles use vision-guided navigation systems to transport irregularly shaped and fragile materials. Path-planning algorithms let such vehicles travel through changing layouts while the plant continues working.

Every so often, they interface directly with bespoke warehouse management systems for instantaneous order updates. Their designs can include unique attachments, including robotic arms or special grippers, for truly customized operations.

HELI: Dependable Choice for Automatic Guided Vehicles

With years of experience in developing industrial vehicles, Anhui Heli is a trusted automatic-guided vehicle manufacturer. Our AGV solutions integrate advanced navigation technology, intelligent control systems, and industry scenario know-how to provide customers with dependable products and services.

Here are two automated guided vehicles that satisfy different industrial needs:

- 1.0t Omni-directional Counterbalanced AGV: Equipped with the lithium battery, it providesdurability and multiple protections, allowing for precise navigation within limited spaces.

- 5-3t Pallet Truck AGV: This compact AGV features precise servo control and enables point-to-point transfer of materials.

We invite businesses to explore such types of automated guided vehicles and how our AGV solutions can boost working efficiency.

Want to improve your operational efficiency with AGV solutions? Explore types of automated guided vehicles from HELI and schedule a consultation with HELI experts now!